Products using this "POLAK" are scheduled to be released in February 2023 by URBAN RESEARCH DOORS, a brand developed by Urban Research Co., Ltd. that proposes long-life products that are good for the environment under the theme of "comfortable living."

In response to the global trend of SDGs and sustainability, the fashion industry is paying more attention to environmentally friendly materials, and many products using these materials can be seen.

POLAK, which was originally developed by TOYOSHIMA, is a 100% plant-derived material created by blending fibers collected from kapok, a plant native to Southeast Asia, with PLA, a biomass raw material made from starch from corn and sugar cane.

Until now, kapok was difficult to process into fiber, and development of textile products did not progress, leading to commercialization, so in Southeast Asia, where many kapok trees grow naturally, it was treated like scrap wood and discarded. With the development of technology, a method of blending kapok, which had been treated as waste material, with polyester and processing it into fibers has been born, and we have developed 100% plant-derived fibers by blending them with PLA. We have succeeded in transforming things that would otherwise be discarded into 100% plant-derived, environmentally friendly materials. Compared to petroleum and animal-derived fibers, it has a lower impact on the environment and does not require large-scale cultivation or deforestation, so it is expected to contribute to a recycling-oriented society.

Furthermore, in terms of functionality, Kapok's lightweight (1/8 the weight of cotton), hygroscopic heat absorption that absorbs moisture and generates heat when it is cold, and moisture absorption and release properties that release moisture when it is hot to make it cool and comfortable, so it can be used as a filling material for apparel products and bedding.

In February 2023, the 2023SS product using "POLAK" as a material will be released by URBAN RESEARCH DOORS, a brand developed by Urban Research Co., Ltd. that proposes long-life products that are good for the environment under the theme of "comfortable living."

In the future, we aim to have POLAK used in various situations such as materials such as soil improvement sheets related to civil engineering, materials for handicrafts, and bedding as a material that balances sustainability and functionality, in addition to apparel products.

■About POLAK

"POLAK" is a 100% plant-derived material created by blending fiber collected from kapok, a plant native to Southeast Asia, with PLA, a biomass raw material made from starch from corn and sugar cane. Compared to petroleum and animal-derived fibers, it has a lower impact on the environment and does not require large-scale cultivation or deforestation, so it can contribute to a recycling-oriented society.

HP: https://po-lak.com/

〈What is POLAK's raw material, Kapok? 〉

Kapok is a plant native to the island of Java, predominantly. Fibers are collected from the fruits of the 10~30m high Qiao tree. Kapok fiber is characterized by a straw-shaped hollow structure with a fiber length of 18~27mm and a diameter of about 0.02mm. Because it is lightweight, has excellent heat retention and water resistance, it has been used in life preservers and futon filling, but due to the high spinning difficulty, it currently has a smaller market share than other fibers. Therefore, TOYOSHIMA created the 100% plant-derived filling functional sheet "POLAK", which is manufactured from kapok fiber in the form of cotton sheets using 's unique technology.

〈Reason for lightness and warmth〉

・Hollow structure

The hollow rate of kapok fiber is 70~80%.

Since it has the highest hollow ratio among natural fibers, it is characterized by being 1/8 the weight of cotton.

・Heat retention

The inside of the sheet is air-pack-shaped and has low thermal conductivity, which has an insulating effect.

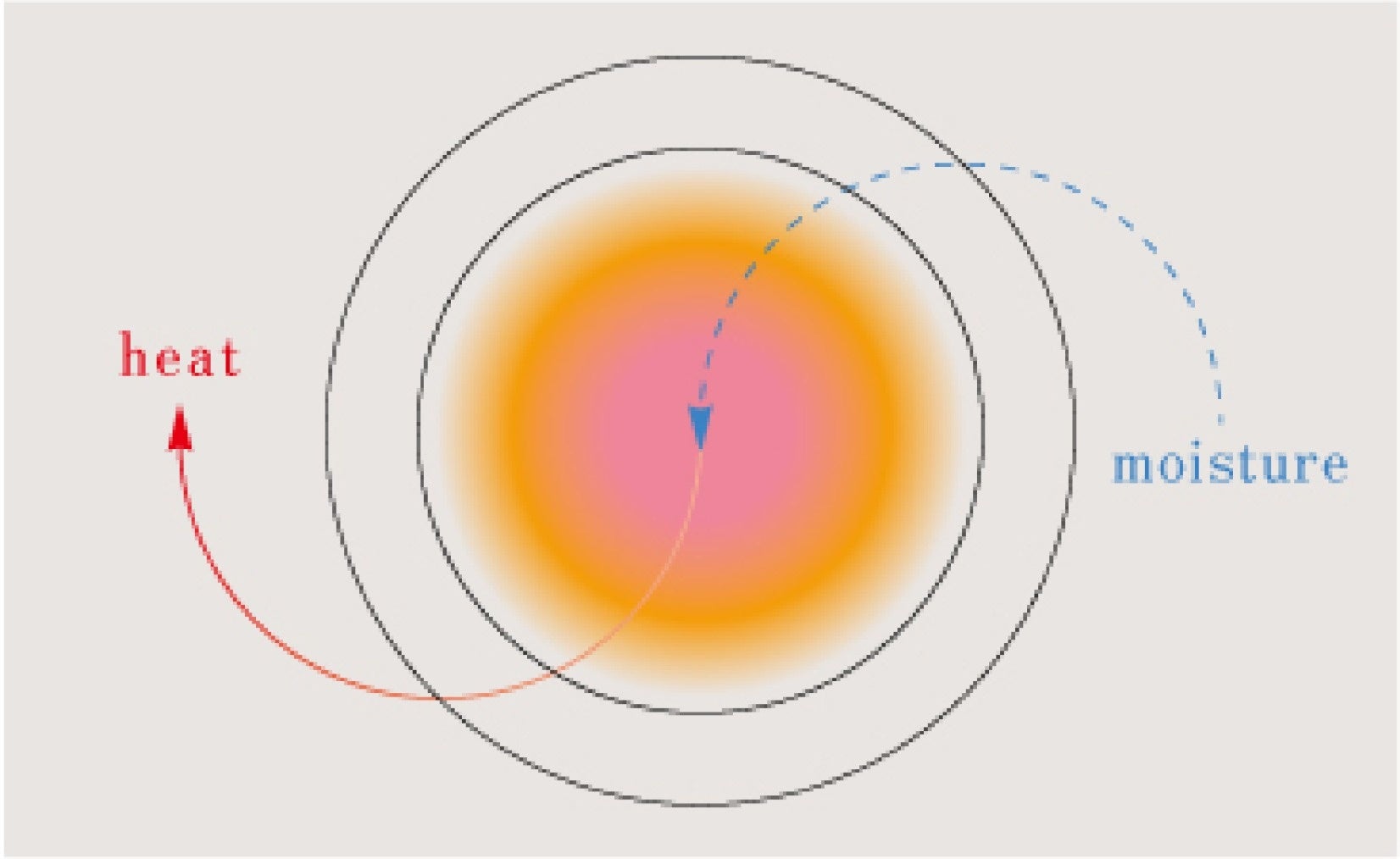

・Hygroscopic exothermic property

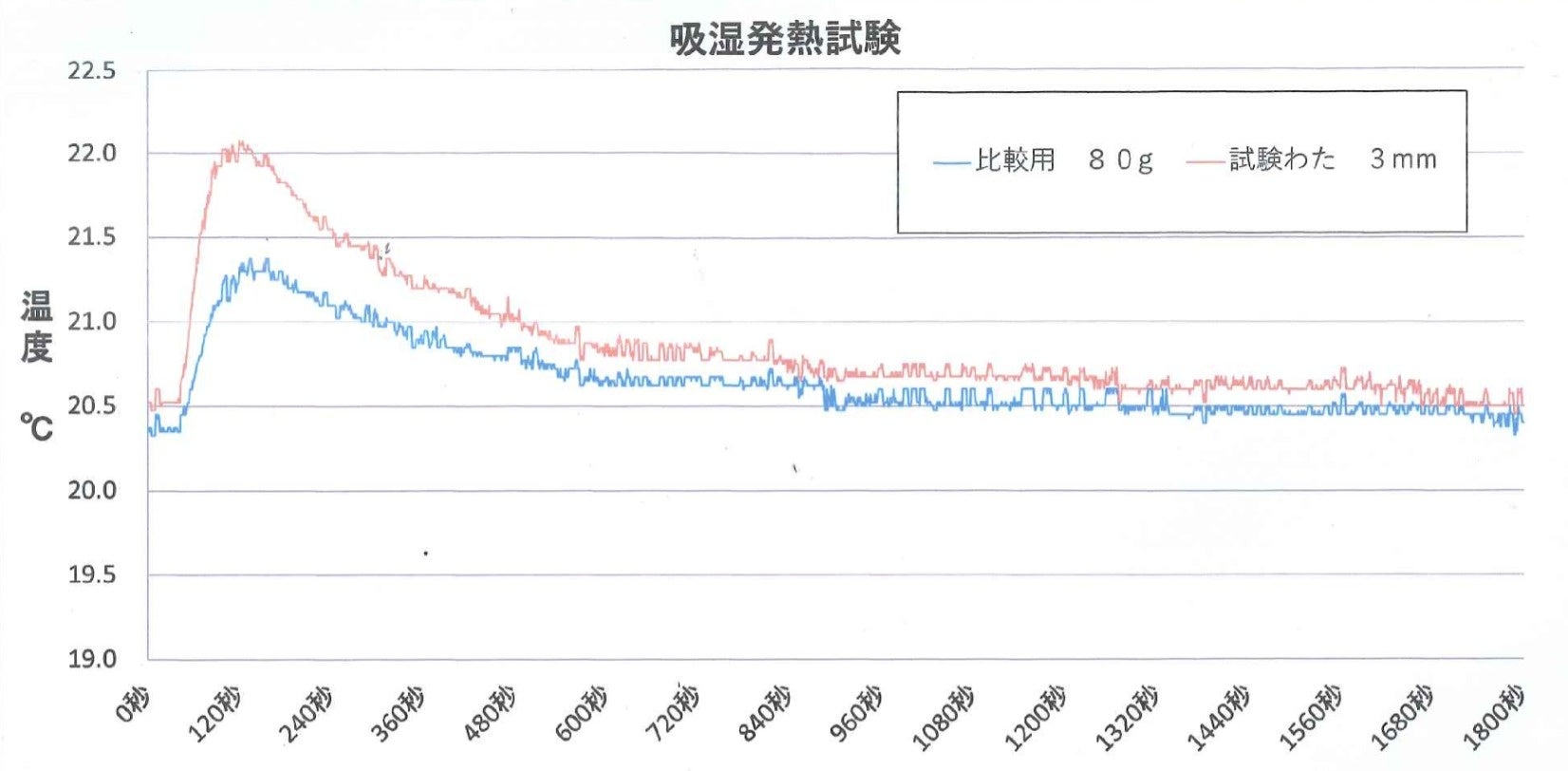

The hollow part of the kapok fiber absorbs the water emitted from the body, and generates heat using the condensation heat generated when water vapor turns into water. * Effect measured by Nissenken Quality Evaluation Center

▶ Nissenken Quality Evaluation Center

Data of hygroscopic heat generation test of Kapok filling sheet