豊島株式会社には、国連総会でSDGsが採択される以前から、地球に優しい素材の普及に取り組んできた歴史があります。これからも、トレーサビリティやサステナビリティを確保した素材の開発、普及に努め、原料の調達、製造から物流、販売、リサイクルに至るまで、サプライチェーン全体での持続可能なビジネスを構築していきます。

脱炭素社会への取り組み

ファッション業界がもたらす環境負荷は世界中で大きな問題となっています。環境省の発表によると、原材料の調達から紡績や縫製、商品の輸送までにかかる環境負荷は、1年間でCO2排出量にして約9万トン、水は約83億m3にものぼります。豊島株式会社は、ファッション産業が自然環境及び社会に与える影響を把握し、業界全体で解決策を導き出し、カーボンニュートラルに向けた取組を推進していきます。

目標と実績

2050年温室効果ガス排出の実質ゼロを目指す2030年度目標値

2050年度目標値

107期実績(*2)

Scope1+2

早期に実質ゼロを目指す

0

―(957t)

各種クレジット購入によるオフセットを実施

Scope3

JSFA(*1)に合わせて設定中

0

測定中

※排出係数:環境省排出原単位データベースおよびIDEAv3より引用

(*1) ジャパンサステナブルファッションアライアンス(JSFA)。ファッションおよび繊維業界の共通課題について共同で解決策を導き出す企業連携プラットフォーム(2021年8月より加盟)

(*2)算出期間:2023年7月~2024年6月30日

2023年7月~2024年6月30日においては、自社利用している不動産においてCO2フリー電力を使用したことで通期の約8割相当に当たる826tのCO2排出を削減し、排出量131tについては各種クレジット購入によりオフセットいたしました。これにより、Scope1、2におけるCO2排出量のネットゼロを達成いたしました。

循環型社会への貢献

循環型社会の構築に寄与するため、廃棄物の削減と再資源化に取り組んでいます。また、最新テクノロジーを活用することでサプライチェーン全体の効率化や環境負荷軽減を図り、持続可能な産業構造を確立していきます。

再資源化の推進

不要になった繊維製品を素材ごとに回収・再生するプロジェクト「WAMEGURI(ワメグリ)」や、ポリエステル・ナイロン・アクリルの3 素材を最先端技術により再活用するプロジェクト「TecRecyc(テックリサイク)」など、これまで廃棄されてきた素材を再び活用することでCO2 排出量を削減し、環境への負荷を低減する取り組みを推進しています。

01

服は国内で循環するという新しい常識・文化をつくるWAMEGURI(ワメグリ)

不要になった衣服や原料を集めてリサイクルし、新たな製品に生まれ変わらせるプロジェクト「WAMEGURI(ワメグリ)」。回収・裁断・紡績を全て国内で実施し、ペットボトル・コットン・ウール・羽毛の4つの素材を、環境に優しいリサイクルシステムで、新たな製品に生まれ変わらせます。リサイクル工程が“日本国内”で行われることを特徴とし、「服は国内で循環するもの」という新しい常識・文化を作るべく、2022年1月より開始しています。

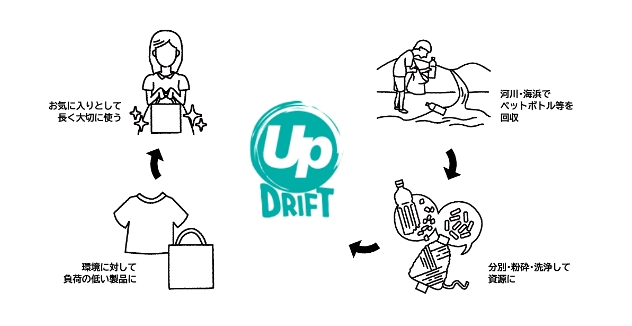

UpDRIFT

地方自治体及び、企業と連携して行う海・川・森のクリーンアップ活動で回収したペットボトルゴミ等を、アパレル製品原料となる繊維「UpDRIFT(アップドリフト)」に生まれ変わらせます。

02

最先端技術によるグローバル再生素材TecRecyc(テックリサイク)

ファッション業界がもたらす環境負荷は、世界中で大きな問題となっています。再生繊維への取り組みが急がれる中、衣類の中でも最も生産量の多いポリエステルについては、再生繊維の市場シェアが2020年の14.7%から2021年の14.8%へと微増している状態です※1。このようなファッション業界の状況を受け、豊島株式会社が展開するプロジェクトが、グローバル再生素材「TecRecyc(テックリサイク)」です。TecRecycは、多岐にわたるリサイクル素材開発のトライアンドエラーを繰り返し、ポリエステル、ナイロン、アクリル、3つの繊維の再生を可能にしました。これまで廃棄されてきた素材を再び活用することで、CO2排出量の軽減など環境への負荷を減らすことにチャレンジしていきます。

また、「TecRecyc」を通じて一般社団法人more treesへの寄付を実施することで、カーボン・オフセットに貢献しています。例えば「TecRecyc」のタグを下げた商品を1枚購入すると、10円が森林保全団体へと寄付され、それを試算すると約1,000gのカーボンオフセットに寄与します。

※1 出所 Preferred Fiber& Materials Market Report2022

廃棄物の削減

最新テクノロジーを活用することで、資源を大切にしたものづくりと、無駄なものを世に出さないものづくりを提案していきます。また、サプライチェーン全体の効率化や負荷軽減を図り、持続可能な産業構造を確立していきます。

01

次世代のモノづくりプラットフォームBUZZU

さまざまなアイテムの素材・型・デザインから好きなモノを選んで自由にカスタマイズできるモノづくりプラットフォームを運営しています。

02

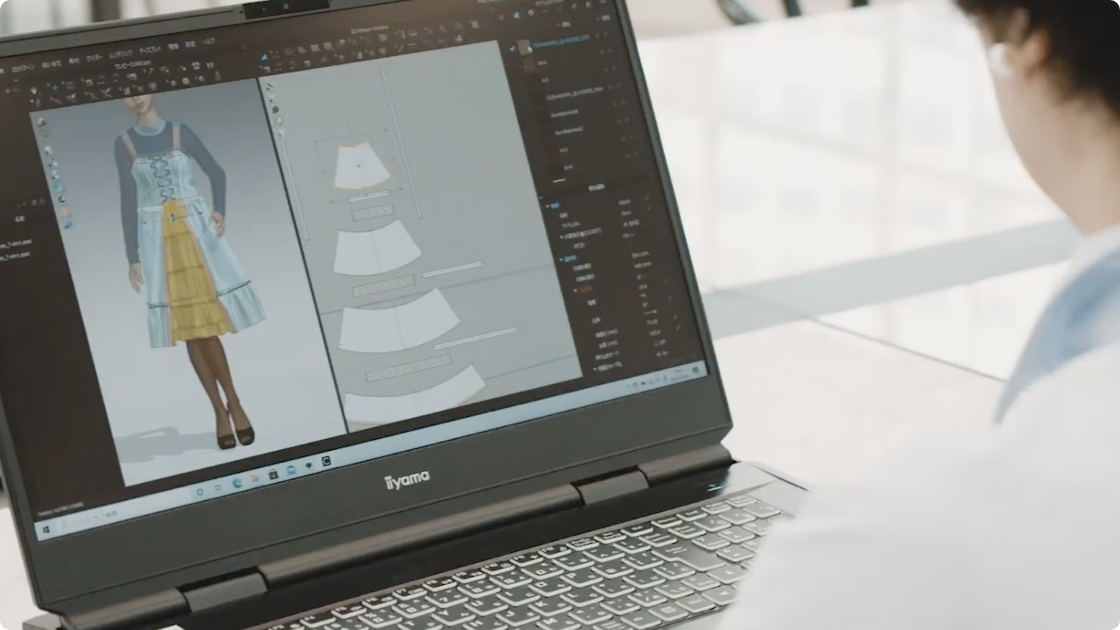

3DCGを活用したサンプルづくり

3DCGを活用しアパレルの生産工程の効率化を実現する「VIRTUAL CLOTHING(バーチャルクロージング)」など、3DCGを取り入れることで、生産スピードの向上、需要予測の精度向上、受注生産体制の実現などアパレル業界の根本的な課題の改善に取り組んでいます。

環境配慮型素材の開発

30年以上前から続く環境配慮型素材への取り組み

豊島株式会社には、国連総会でSDGsが採択される以前から、地球に優しい素材の普及に取り組んできた歴史があります。1990年から手掛けている「テンセル」は、土に還る、環境に負荷を与えないやさしい素材です。2005年にはオーガニックコットン普及プロジェクト「オーガビッツプロジェクト」を開始し、化学肥料を使わず、人にも環境にもやさしい有機の綿花栽培を広める取り組みをしています。

また、2015年に開始した廃棄予定の食材やコーヒーの出涸らしなどを染料として活用する「FOOD TEXTILE(フードテキスタイル)」は、パートナーである食品関連会社、コラボレーション会社ご協力のもと、多くの消費者の皆さまにご支持いただけるブランドへと成長しています。

トルコの紡績グループUCAK TEKSTIL(ウチャクテクスティル)社との日系企業向け独占販売契約で実現した「TRUECOTTON(トゥルーコットン)」は、農場と紡績工場の特定ができるオーガニックコットンです。綿花農場で働く人が健康で明るい毎日を送ることができ、綿花を紡いで糸をつくる紡績工場で働く人も、明日も元気に働こうと思える環境、そんな裏付けのある場所でつくられた安心安全なオーガニックコットンです。生産者や手法、土地を大切にするという価値観が、ファッションの世界に拡散することを私たちは目指しています。理念である「誠実と信頼・堅実と積極」のもと、嘘をつかず、正直にコツコツと活動していくことが豊島の大切にしている考えです。