TOYOSHIMA 's Five Missions (Five Value Creation)

- home

- SUSTAINABILITY

- Toyoshima SDGs Declaration

- 豊島の5つの使命(5つの価値創造)

Toyoshima has set 5 SDGs materiality (important issues for realizing a sustainable society),

we have formulated a way of thinking that will serve as the basis for solving these problems.

First of all, TOYOSHIMA 's SDGs are "Human Resource Development," which we have consistently stuck to since our founding.

On top of that, we will do all kinds of activities that contribute to manufacturing that contributes to future society and to the sustainability of the earth and local communities.

We will also promote the construction of ICT infrastructure that connects supply chains, connecting people, goods, and resources,

we will contribute to the realization of a consumer society that can sympathize with sustainable values.

未来を担う人財づくりTOYOSHIMA SUSTAINABLE ACTION 01

The foundation of TOYOSHIMA 's human resource development is based on the stance of "honesty and truthfulness," "earnest and earnest efforts," and "fulfilling one's responsibilities." By giving each employee discretionary power based on these foundations, we have created a "personalized group" that is strong against adversity, and we have overcome various environmental changes so far. This is TOYOSHIMA 's history, which has continued for nearly 180 years, and is part of TOYOSHIMA 's DNA. The development of materials such as Orgabits and Tencel, as well as the construction of the ODM business that pioneered other companies, were born from TOYOSHIMA 's history and DNA.

We will continue to develop human resources with the ability to create new value and achieve innovation.

Reflecting the voices of the field

フェムテック商品を展開する「Hogara」は、豊島の女性職員が働きながら抱えていた悩みを解決しようと立ち上げたブランドです。

産学連携での商品開発など、現場のリアルな声をモノづくりに反映させながら新たな変革を生み出しています。

Support the challenge

We encourage young employees to take on new business challenges that transcend departmental boundaries. We are promoting the creation of next-generation businesses, such as the collaboration of crowdfunding Makuake X Toyoshima.

Diversity

時代の変化や市場のグローバル化が進む中で、国籍や性別に関係なく、さまざまな社員が活躍をしています。ダイバーシティな人財活躍の場を継続して作っていくことで、新たな価値創造や海外展開を進めています。

持続可能な仕組みづくりTOYOSHIMA SUSTAINABLE ACTION 02

TOYOSHIMA is promoting initiatives to reduce CO2 emissions and reduce environmental impact by reusing materials that have been discarded. In addition, through the use of the latest technologies and partnerships, we will establish a sustainable industrial structure by improving the efficiency of the entire supply chain and reducing environmental impact.

Clothing recycling project

不要になった衣服や原料を集めてリサイクルし、新たな製品に生まれ変わらせるプロジェクト「WAMEGURI(ワメグリ)」では、ペットボトル・コットン・ウール・羽毛の4 つの素材を、環境に優しいリサイクルシステムで、新たな製品に生まれ変わらせています。

Development of recycled materials

豊島は、ポリエステル、ナイロン、アクリル、3つのグローバル繊維の再生を可能にしました。これまで廃棄されてきた素材を活用することで、CO2 排出量の軽減など環境への負荷を減らすことにチャレンジしていきます。

パートナーシップ活動

豊島と㈱JEPLANは「BRING Material™」の糸販売に関するオフィシャルパートナーシップを締結しました。100%繊維由来の再生ポリエステル樹脂「BRING Material™」は、これまで「樹脂」として販売されてきましたが、これによりアパレル製品の素材である「糸」による供給体制が構築されます。

イノベーティブな事業づくりTOYOSHIMA SUSTAINABLE ACTION 03

TOYOSHIMA, we are not only manufacturing products that meet market demand, but also presenting new values to society and Creating innovative businesses new values together with consumers who sympathize with us. In addition to sustainable manufacturing that reduces the environmental impact of the production process as much as possible, we are developing human resources who can handle the latest technology and are trying to create new values in our daily lives.

テクノロジー人材の

育成

At TOYOSHIMA, we handle various 3D design software such as BROWZWEAR, CLO, and APEX, and the Design Planning Dept. runs an in-house course to train 3D modelists. So far, a total of 50 people have received training and are starting to put it to practical use. We will work with digital vocational schools and CG processing companies to improve our technology and provide new values and services.

(Design Planning Dept.)

Sustainable

manufacturing

It is possible to reduce the environmental load by using data, such as reducing the number of product samples at the planning stage, consolidating logistics, reducing overproduction and loss of sales opportunities. TOYOSHIMA, we are promoting the creation of a sustainable manufacturing system by making actual proposals while actively utilizing 3D design software and various data.

(Design Planning Dept. /DX Promotion)

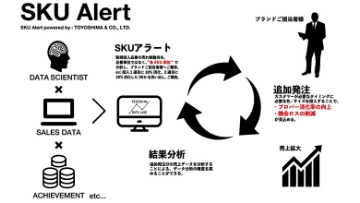

Increased prediction accuracy

by data lab

This is an initiative aimed at reducing loss of sales opportunities for business partners. After sharing sales performance data from business partners, we analyze it by exclusive data scientists. By analyzing with a unique method that incorporates AI, we support you in deciding on additional orders for the necessary colors/sizes at the right time. As a result, we have received feedback that it also led to an increase in the digestion rate of Probar.

(System Plannning Dept., Data Lab)

地球に優しい素材づくりTOYOSHIMA SUSTAINABLE ACTION 04

Through the Orgabits Project, in collaboration with business partners and NPOs, TOYOSHIMA supports organizations that are doing good things for the environment and society. We are doing conservation work. In addition, we are working to create sustainable materials on a global scale, such as collaborating with organic cotton production areas in Turkey to promote the spread of traceable cotton.

Blue ocean

project

A project to conserve marine animals such as sea turtles and the coastal environment, as well as the lifestyle and culture of people living near the coast and fishermen. As one of the Orgabits projects, we attach tags to products of brands that support this activity, and donate 10 yen per tag.

Borneo Environmental Conservation

project

A project to protect the forests lost due to large-scale deforestation on Borneo Island, create a rich environment for wild animals, and create a future where animals and humans live together. As one of the Orgabits projects, we attach tags to products of brands that support this activity, and donate 10 yen per tag.

Switching to traceable cotton

Who made this cotton?

TOYOSHIMA 's partner, UCAK TEKSTIL in Turkey, can manage everything from farms to spinning, so you can see the producer's face = producing safe and secure organic cotton. In 2019, TOYOSHIMA concluded an exclusive yarn trading contract with Japanese companies and is promoting the spread of traceable organic cotton.

人に優しい地域づくりTOYOSHIMA SUSTAINABLE ACTION 05

TOYOSHIMA established the Toyoshima Welfare Fund in 1973, and has continued its activities to serve the local community and contribute to the development of a welfare society.

In addition, as a company that can develop together with the local community, we are engaged in various initiatives together with our employees, such as cultivating TOYOSHIMA 's unique Japanese cotton and supporting the areas affected by the Great East Japan Earthquake.

Cleaning service

As part of the activities of the Toyoshima Welfare Fund, we have been conducting local cleanup activities since 1976. We also contribute to local welfare by donating nursing care and school supplies to welfare facilities for the elderly and children's schools.

Cultivation of Japanese cotton

What are clothes made of? In TOYOSHIMA, Japanese cotton is grown on organic farmland in Watarase and on the rooftops of the Tokyo Head Office. The experience of manufacturing that begins with sowing seeds leads to learning the origin of work.

CliniClowns

project

A project to support CliniClowns, who regularly visit the rooms of hospitalized children to support their growth. As one of the Orgabits projects, we attach tags to products of brands that support this activity, and donate 10 yen per tag.